The diversity of expanded metals pushes us to continually develop and improve the processes and standards used in its production. If you have need of a special configuration or material not shown within the website, please use our ‘Contact Us‘ form or give us a call. We can meet your functional or structural need.

Return to our ‘Expanded Metals‘ page, or browse our ‘Expanded Metal Grating‘, ‘Sun Shade & Micro-Mesh‘ and ‘Expanded Mini-Mesh’ pages for product specs of each type. Be sure to view the ‘Expanded Solutions Process‘ page for a technical overview of the process and terminology.

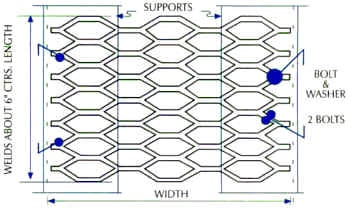

- Expanded metal grating is a very economical walking surface where ever high strength and light weight are required.

- Walking surface is anti-skid, providing safe foothold.

- The open design allows effective sprinkler coverage for fire protection; prevents dirt, grease or snow accumulation; it enables a visual ‘see-through’ area inspection; lowers maintenance costs.

- Expanded grating costs less than bar-type grating and is easier to install in new or replacement applications.

Please Note:

The information provided is for descriptive purposes only – NOT FOR DESIGN